Carrageenan: The Perfect Gelatin Replacer in Vegan Chewy Gummy Candy

Table of Contents

Summary

Gino Biotech is one carrageenan supplier in China. Carrageenan can be used as a thickener, coagulant, and stabilizer in vegan gummy candy.

This article will take you through the carrageenan in vegan chewy gummy candy. Keep reading to learn more.

What is Chewy Gummy Candy?

Gummies, gummy candies, or jelly candies are a broad category of gelatin-based chewable sweets. Gummi bears and Jelly Babies are widely popular and are a well-known part of the sweets industry. Gummies are available in a wide variety of shapes, most commonly colorful depictions of living things such as bears, babies, or worms. Various brands such as Bassett's, Haribo, Betty Crocker, Disney, and Kellogg's manufacture various forms of Gummi snacks, often targeted at young children. The name "gummi" originated in Germany, with the term "jelly" more common in British English.

---From Wiki

What is Vegan Chewy Gummy Candy?

Consumers may ask: What is Vegan Gummy Candy/Sweet? Which Gummy Candies are Vegan? What is Vegetarian Candy? Are there any Kosher, Vegan, or Gelatin-Free Gummy Bears? Could I enjoy some Healthy Vegan Gummies or Vegan Wine Gummies?

We all love chewy gummy candies, like gummy bears, gummy worms, and wine gummies, but unfortunately, most of them contain a non-vegan ingredient: GELATIN.

So the best answer to the above questions is that "Completely free from gelatin (animal source), contains no artificial colors (Especially the carmine, which is a red pigment made from the crushed female cochineal insect) or flavors."

Carefully check out the ingredients list before you enjoy the Gelatin-Free Candy. Be sure to check the label!

What is Carrageenan?

Carrageenan can be used as a thickener, coagulant, suspending agent, emulsifier, and stabilizer because of its coagulability, solubility, alkalinity, and other characteristics. It has a wide range of uses in the food and other industries.

The use of carrageenan to make soft jelly candies has a long history in China. It has a strong fruit flavor, moderate sweetness, and refreshing and non-sticky, so it is very popular among consumers.

It can be used to make general fruit jelly candies, or it can be made into high-end fruit jelly candies by adding nutrients, or it can be made into nourishing jelly candies by adding nourishing ingredients.

Today we focus on the application of carrageenan in vegan chewy jelly candy manufacturing.

Raw Materials of Vegan Chewy Gummy Candy

Carrageenan Jelly Candy is made of white granulated sugar and syrup as the main raw materials, carrageenan as a gelling agent, supplemented by flavors and colors.

Classifications

Carrageenan vegan chewy gummy candies are classified as follows according to taste and appearance:

Type

General Carrageenan Jelly Candy

Dosage

0.8-1.2%

Taste & Appearance

Transparent and opaque soft candies can be made, and the taste is not sticky. The elastic and opaque soft candies are generally added with starch-based opacifiers, such as corn sugar.

Acidic Carrageenan Jelly Candy

1.0-1.5%

A sour agent is added when making soft candies to obtain sweet and sour soft candies with the same taste and better flavor.

Pouring Jelly Candy

Use a pouring machine to pour into the mold and form it at one time. This soft candy is directly boiled to the right moisture without drying, the taste is chewy, and the surface is bright and very transparent.

Other hydrocolloids used in chewy gummy candies include gelatin, agar, pectin, modified starch, etc. The tastes are different and each has its own characteristics.

How to Make Vegan Candy?

How to make vegan gummy candy? How to make gummy bears without gelatin? Please kindly check the below suggested Vegan Gummy Candy Recipe

Vegan Gummy Candy Recipe

Ingredients for General Carrageenan Jelly Candy:

Water: 35kg

Compound Carrageenan Powder: 1.2kg

Syrup: 60kg

White Sugar: 40kg

Ingredients for Acidic Carrageenan Jelly Candy:

Water: 35kg

Compound Carrageenan Powder: 1.4kg

Syrup: 60kg

White Sugar: 40kg

Citric acid: 0.5kg

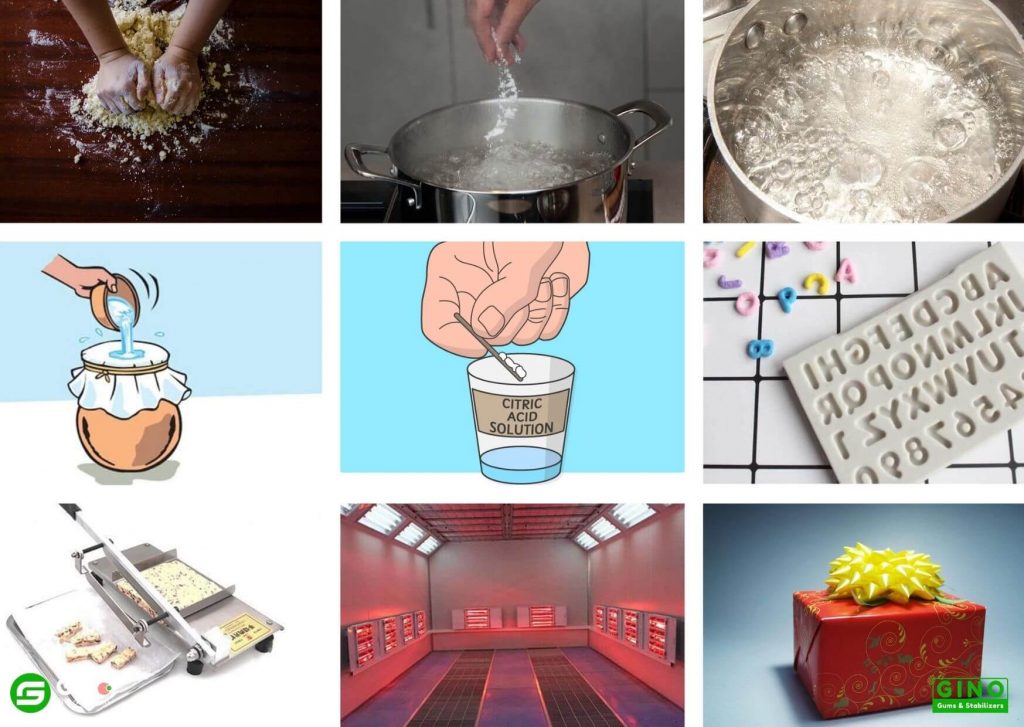

Instructions For Vegan Gummy Bears

Operation points VS Matters needing attention:

-

Premix

First mix carrageenan and white granulated sugar in the formula at a ratio of 1:4, and then add 35kg of water for swelling for about half an hour. (White granulated sugar needs to be ground into fine powdered sugar in order to be fully mixed with carrageenan).

-

Dissolving Sugar

Add 60kg of syrup in a jacketed pot or a sugar pot, then add the remaining white sugar, heat and stir to about 90 degrees Celsius. Stir while adding the white sugar to avoid lumps.

-

Melt

Add the already swollen carrageenan and white sugar mixture, and continue to heat up to boiling.

-

Filtration

The sugar solution is filtered with an 80 mesh screen to remove impurities.

-

Boil Sugar

After filtering, continue to cook to 106-107 degrees Celsius, and stop heating when the dry matter reaches about 75.

-

Acid Adjustment

Dissolve citric acid with the same amount of water, and when the sugar solution is slightly cold, put it into the syrup together with the color and flavor, and stir well.

-

Pouring Into The Mold

Quickly pour the sugar liquid onto a clean cooling plate coated with a small amount of vegetable oil. The plate should be flat to keep the sugar liquid at a certain thickness, static and skimming the surface of the air bubbles. The speed should be fast when pouring the pan, so as to avoid the "tail dragging" phenomenon caused by the sugar liquid cooling too fast.

-

Cooling

After the sugar liquid is poured into the pan, cool naturally until it solidifies into a jelly form.

-

Cutting And Forming

After the sugar liquid is cooled, use a hob with a well-adjusted blade to cut into pieces.

-

Drying

Place the sugar cubes on a metal plate coated with a small amount of oil at a certain interval, and place them in a drying room to dry. The temperature of the drying room is strictly controlled at 55-60 degrees Celsius, especially at the beginning, the temperature should not be too high, so as to avoid crusting on the surface and affecting water distribution. Place in the drying room for 36-48 hours.

-

Cooling

After drying for about 4 hours, remove and cool to room temperature.

-

Packaging

The cooled sugar cubes are selected and packaged into finished products.

Technical Requirements

Sensory Indicators

2. Form: Complete block shape, no bubbles, uniform size and no deformation.

3. Impurities: No obvious visible impurities.

4. Color and fragrance: In line with the color and luster of the product, the color is bright, the sugar body is bright and transparent, the fragrance is pure, the taste is normal, and there is no peculiar smell.

5. Texture: The surface is smooth, shiny, non-living, non-sticky, no crusty.

Physical & Chemical And Sanitary Indicators

2. Reducing sugar: 20-32%

3. Meet GB national health standards

Product Advantages

Compared with other jelly candy, the jelly candy made with carrageenan has the following advantages:

- Good taste,

- High transparency,

- Bright color,

- Low cost.

At the same time, carrageenan has a wide application range, fast solidification speed, short drying time, and energy saving.

The production process of carrageenan is simple, which is suitable for manual operation and mechanized continuous production. The development prospect is very broad.

Dos and Don’ts

1. The compound jelly candy powder based on carrageenan is not easy to dissolve under high sugar concentrations, so it is recommended to dissolve it with water first. Otherwise, it is easy to produce "trachoma", that is, small colloidal particles one by one.

2. Pay attention to reducing sugar content. The content of reduced sugar is too low, the storage time is long and easy to return to sand; If the reduced sugar content is too high, it is easy to fail when pouring into the mold (not forming, drawing).

3. Possible reasons for not forming or drawing:

| Possible Cause | Solution |

| Too Long Cooking Time | The longer the time, the greater the chance that the colloid will be destroyed. Generally, it can end at 107 degrees, except for pouring jelly candy. |

| Too Low Moisture Content | The water content added at the beginning is small, which causes the colloid to not fully dissolve. It is recommended to swell the colloid with water in advance (not absolutely necessary). Do not add too little water, about 30% is recommended. At the end of the cooking, there is little water, and the colloid does not have enough water to form a gel. This is not very common. |

| The Acid Syrup Causes The Overall Environment To Be Acidic | Acidity can easily destroy colloids (except for pectin) at high temperatures, resulting in an insufficient amount of colloid to form a gel. It is recommended to add acid in the final stage, especially before pouring the mold. And the acid needs to be dissolved in water in advance and then added, and it needs to be stirred quickly when added. Add sodium citrate (potassium) to control the ph value of the syrup. If it is not sour jelly candy, you can add more, such as 0.1-0.4%; if sour sugar, add 0.08-0.2% |

| Low Amount Of Colloid | It is not very common. Generally speaking, if the amount of colloid is small, it will produce a slightly tender taste. If the drying temperature is high or the time is too long, there will be a wire drawing after drying. |

4. You can add colorful materials, such as carrot sauce after the glue is boiled, but the proportion of soft sugar powder should be calculated.

Carrageenan in Gelatin-Free Chewy Gummy Candy

Carrageenan Supplier in China

Related Articles

We are a biotech company specializing in the research, development, and commercialization of innovative and technological food additives hydrocolloids Agar Agar, Carrageenan, and Tailor-Made Stabilizer Solutions.

With the extended know-how and experience in the research, application, and use of Hydrocolloids, we could provide one-stop-shop customized solutions perfectly matched to the needs of our customers.

Our products cover the needs of the Meat, Dairy, Bakery, Confectionery, and other industrial sectors.