For over 10 years, Gino Biotech has been a major supplier of food hydrocolloids. With our variety of plant-based gums & stabilizers, we can create tailor-made hydrocolloid solutions perfectly matched to the needs of our customers. READ MORE

Agar vs Pectin: Understanding the Differences and Choosing the Right Gelling Agent

Agar vs Pectin: Understanding the Differences

Facebook

Twitter

LinkedIn

In the world of food science, pharmaceuticals, and industrial applications, gelling agents play a crucial role in texture, stability, and overall product performance. Two of the most commonly used natural gelling agents are agar and pectin . While both are widely used for their thickening and gelling properties, they come from different sources and behave quite differently under various conditions.

In this article, we’ll take a deep dive into agar vs pectin , exploring their origins, functional properties, and ideal applications to help you choose the right one for your specific needs.

1. What is Agar?

Agar, also known as agar-agar, is a natural polysaccharide derived from red seaweed (primarily Gelidium and Gracilaria species). It has been used for centuries, especially in Asian cuisine, as a gelling agent and vegetarian alternative to gelatin.

Key Characteristics of Agar:

- Source : Red algae/seaweed

- Gel Strength : High

- Setting Temperature : ~32-40°C (90-104°F)

- Melting Temperature : ~85-95°C (185-203°F)

- pH Stability : Stable over a wide pH range (5-8)

Agar forms firm, brittle gels and is thermoreversible - meaning it can melt and re-solidify without losing its properties. This makes it ideal for use in microbiology media, desserts, jellies, and even some pharmaceutical formulations.

2. What is Pectin?

Pectin is a naturally occurring polysaccharide found in the cell walls of fruits, particularly apples and citrus peels. It’s commonly extracted during fruit processing and is widely used in the food industry, especially in jams, jellies, and confectionery products.

Key Characteristics of Pectin:

- Source : Fruit (e.g., apple pomace, citrus peel)

- Gel Strength : Varies by type (high methoxyl vs low methoxyl)

- Setting Mechanism : Requires sugar and acid (for high methoxyl) or calcium (for low methoxyl)

- pH Sensitivity : Works best in acidic environments

- Thermal Reversibility : Not fully reversible like agar

Pectin produces softer, more elastic gels compared to agar and is highly dependent on pH, sugar content, and temperature during gelation.

Agar Agar vs Pectin: A Comparative Overview

Feature | Agar | Pectin |

Source | Seaweed | Fruits (apple, citrus) |

Gel Texture | Firm, brittle | Soft, elastic |

Setting Temperature | 32-40°C | Depends on type |

Requires Sugar/Acid | No | Yes (especially HM pectin) |

Thermal Reversibility | Yes | Limited |

pH Stability | Wide range | Acidic environment preferred |

Applications | Desserts, microbiology, pharma | Jams, jellies, dairy, beverages |

3. When to Use Agar vs Pectin (Expanded Guide)

Choosing between agar and pectin isn’t just about availability or cost - it’s about understanding how each gelling agent interacts with your formulation. Here’s a deeper look at when to use each, based on specific functional requirements and end-use applications.

✅ Choose Agar When:

1. You Need a Firm, Heat-Resistant Gel

Agar is known for forming stiff, brittle gels even at low concentrations (as little as 0.5%). Its high melting point (~85-95°C) makes it ideal for products that undergo heat treatment or need to maintain shape in warm environments.

Ideal Applications:

- Bakery fillings and glazes

- Hot-filled desserts or jellies

- Microbiological growth media (agar plates)

- Vegan gelatin substitutes in confectionery

2. Your Recipe Lacks Sugar or Acid

Unlike pectin, agar doesn’t require sugar or acid to form a gel. This makes it perfect for savory dishes, low-sugar formulations, and dairy-based gels.

Example: Plant-based cheese analogs, custards, or yogurt gels where sugar content must be minimized.

3. You Want Clean Label, Vegetarian/Vegan Options

Agar is plant-based and derived from seaweed, making it suitable for vegetarian and vegan diets. It also has a clean label appeal, often listed simply as “agar” or “seaweed extract.”

Use Case: Meat alternatives, vegan puddings, and halal/kosher-certified products.

4. You're Producing Industrial or Scientific Products

Beyond food, agar is widely used in microbiology, pharmaceuticals, and cosmetics due to its stability and reproducibility.

Applications Include:

- Culture media for bacteria and fungi

- Sustained-release drug delivery systems

- Thickener in lotions and gels

✅ Choose Pectin When:

1. You’re Making Jams, Jellies, or Fruit-Based Confections

Pectin is naturally present in fruits and plays a key role in fruit structure. High methoxyl (HM) pectin works best in high-sugar, acidic environments - exactly the conditions found in traditional jams and jellies.

Typical Formulation:

- 60-70% sugar

- pH 2.8-5

- Cooked until gel point is reached

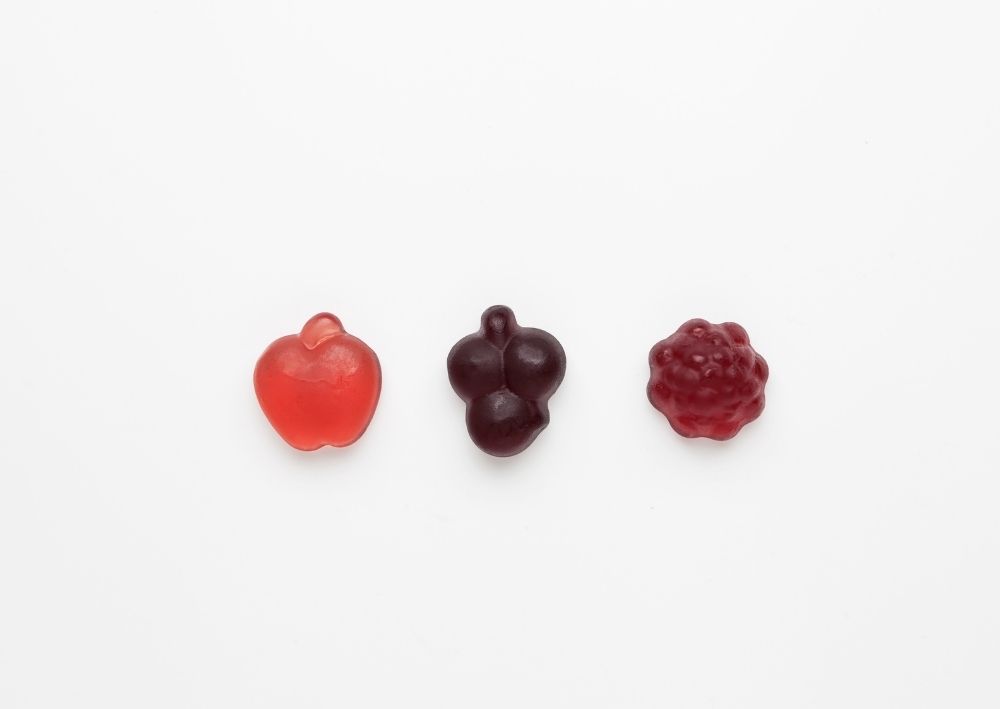

2. You Want a Soft, Elastic Texture

Compared to agar’s firm and brittle texture, pectin produces softer, more elastic gels. This is especially desirable in confectionery like fruit snacks, gummy candies, and soft-centered chocolates.

Tip: Low methoxyl (LM) pectin allows you to create gels without relying on sugar by using calcium ions instead. This is ideal for reduced-sugar or diabetic-friendly products.

3. You Need pH-Sensitive Gelling Behavior

Pectin’s gelation is highly dependent on pH and ionic strength. This can be an advantage if you want to control texture through formulation.

Application Example: Dairy desserts where pH shifts during processing can trigger gelation, enhancing mouthfeel and consistency.

4. You’re Looking for Nutritional Benefits

Some types of pectin act as dietary fiber and have prebiotic properties, supporting gut health. This makes it a functional ingredient in beverages, yogurts, and functional foods.

Trend Alert: Clean-label, natural, and fiber-rich ingredients are in high demand - pectin checks all these boxes.

Agar Agar vs Pectin: Real-World Application Examples

Product | Best Gelling Agent | Why? |

Jam | Pectin | Needs sugar and acid to gel; soft, spreadable texture |

Vegan Gummy Candies | Agar or Pectin (depending on texture desired) | Agar gives chewy bite; pectin offers elasticity |

Yogurt Dessert | Pectin | Enhances texture and stabilizes proteins under acidic conditions |

Bacterial Culture Media | Agar | Heat-stable, supports microbial growth, non-nutritive |

Reduced-Sugar Jelly | LM Pectin | Gels with calcium, not sugar |

Bakery Fillings | Agar | Maintains shape during baking, heat-resistant |

4. Conclusion: Agar vs Pectin - Choosing the Right Gelling Agent Matters

In the agar vs pectin comparison, there is no one-size-fits-all answer. Both are powerful natural gelling agents with distinct properties that make them suitable for different applications. Agar excels in firm, heat-stable gels and is ideal for microbiological, pharmaceutical, and vegan formulations. On the other hand, pectin shines in fruit-based products like jams and jellies, offering a soft, elastic texture that consumers love.

Understanding the functional differences between agar vs pectin allows you to make informed decisions during product development - ultimately leading to better texture, stability, and consumer satisfaction.

Let Us Help You Choose Between Agar Agar vs Pectin

Are you unsure whether agar vs pectin is the best fit for your formulation? Our team of experts specializes in natural hydrocolloids and can help you select the right gelling agent based on your product requirements, processing conditions, and labeling goals.

Contact us today for a free consultation, product samples, or technical support - and let’s find the perfect solution for your next successful product launch!

📞 Call us | 📧 Email us | 🌐 Request a Sample

Buy Agar & Pectin

Recent Posts

About Gino Biotech

We are a biotech company specializing in the research, development, and commercialization of innovative and technological food additives hydrocolloids Agar Agar, Carrageenan, and Tailor-Made Stabilizer Solutions.

With the extended know-how and experience in the research, application, and use of Hydrocolloids, we could provide one-stop-shop customized solutions perfectly matched to the needs of our customers.

Our products cover the needs of the Meat, Dairy, Bakery, Confectionery, and other industrial sectors.