Raw Materials

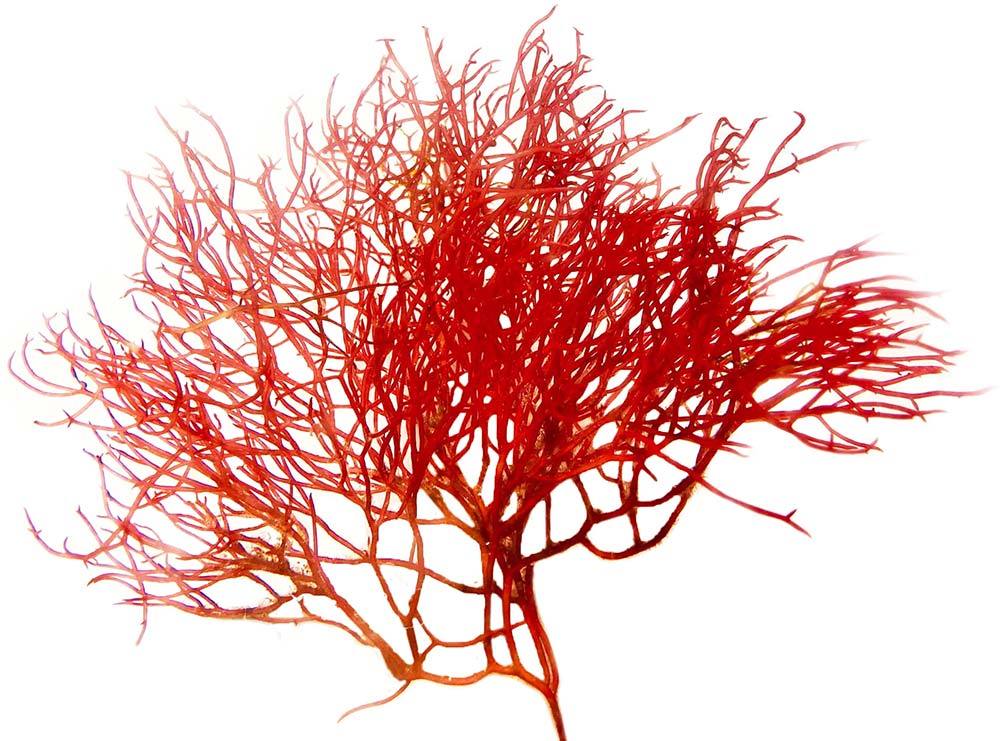

The Natural Red Algae

Without good raw materials, there would be no chance to produce excellent hydrocolloids.

Raw Materials of Carrageenan

Carrageenan is mainly obtained from red algae of Chondrus, Eucheuma.Gigartina, Hypnea and other species of seaweed. There are more than 80 species of red algae containing the basic structure of carrageenan, and no less than 10 species are used for commercial production. These red algae are grown in different marine areas of the world, and the types and varieties of carrageenan obtained are different due to the difficulty in sourcing the species during extraction. Even for the same species source, different process extraction conditions can lead to different molecular weight degradation and differences in product properties.

Eucheuma Cottonii | Irish Moss | Sea Moss

Raw Materials of Agar Agar

Agar is a polysaccharide extracted from red algae of species such as Gelidium sp., Gracilaria sp. and Plerocladia sp. These red algae are grown in the offshore waters of China, Indonesia, Philippines, Korea, Mexico, Portugal, Spain, Chile, Morocco, etc.

Gracilaria | Gelidium

Influencing Factors of Seaweeds Quality

- Growth Period of Seaweed

- Growth Environment of Seaweed

- Growth Zone of Seaweed

- Marine Temperature

- Marine Salinity

- Marine Luminosity

Influencing Factors of Hydrocolloids Quality

- Raw Materials Seaweed

- Equipments

- Technology

Quality Control

We always strictly select the top five domestic and foreign suppliers, and regularly reviews and optimizes their qualification.

We select high-quality seaweed from the natural and non-polluted seas such as the Philippines, Indonesia and Malaysia, and produce high-quality products through advanced processing technology and extraction technology. The quality fully meets the requirements of national standards, EU standard and other domestic and foreigh standards.

We have a 100,000-level purification workshop conforming to the GM standard and strict enforcement of the ISO9001quality management system.

The raw materials are strictly controlled and the finished products are monitored accurately;

Corss validation test of each batch of sampling is taken by quality control department and technical department to ensure the quality of finished products stable and traceable.