Iota Carrageenan

Iota Carrageenan is a high-quality, refined polysaccharide extracted from red algae, ideal for use in dairy, meat, candy, and more. Learn about its applications, benefits, and properties.

Share:

Iota Carrageenan

1. Description

Iota Carrageenan is a refined, high-molecular-weight hydrocolloid extracted from the red seaweed Eucheuma spinosum. Known for its excellent water retention, gelling, and thickening properties, Iota Carrageenan is widely used across various industries, including food, pharmaceuticals, and personal care products.

This premium carrageenan, which is often referred to as calcium-sensitive carrageenan, forms flexible, elastic gels in the presence of calcium ions, making it ideal for creating smooth textures in a range of products.

2. List of Iota Carrageenan We Offer

We offer a wide variety of Iota Carrageenan products to meet the diverse needs of different industries. Below is the detailed list of the available product options:

Buy Iota Carrageenan2.1 By Processing Method

Description: This high-purity carrageenan product has undergone advanced processing, using alcohol and salts for extraction. It has superior clarity and purity due to the removal of fibers.

Features: Higher cost due to advanced processing. It requires a lower dosage to form a gel, thanks to its high purity.

Applications: Ideal for applications where clarity and gel strength are essential, such as dairy products, beverages, jellies, candies, and pharmaceutical formulations.

Description: This product undergoes minimal processing, retaining more of the natural fibers from the seaweed. It is a more economical option, though with slightly lower clarity.

Features: Cost-effective due to less processing. A higher dosage is required to form a gel, as it contains more fiber and insoluble solids.

Applications: Suitable for applications where cost-effectiveness is important, and where clarity is not the highest priority. Often used in processed meats, some food products, and beverages where the clarity is less important.

2.2 By Mesh Size

We offer Iota Carrageenan in various mesh sizes to suit different processing needs:

- 60 Mesh: Coarser particles that are suitable for basic gel-forming applications.

- 120 Mesh: Medium particle size, providing a balance between gel formation speed and texture. Commonly used for general food applications.

- 200 Mesh: Fine particles that dissolve quickly in water and form gels rapidly. Ideal for high-precision applications requiring fast gelation and smooth texture.

2.3 By Viscosity

Our Iota Carrageenan products are available in various viscosities, allowing you to select the right one based on the specific texture and stability requirements:

- 20+ mPa.s: Suitable for applications requiring a lower viscosity and softer gel formation.

- 30+ mPa.s: Ideal for moderate viscosity needs, providing a balanced gel strength and texture.

- 40+ mPa.s: Best for high viscosity applications, offering stronger gel formation and more stable textures.

3. Packaging Options & Loading Quantity

Our Iota Carrageenan is available in various packaging formats to meet your needs:

- Bulk Packaging: Typically 25kg per bagor carton, suitable for large-scale manufacturing.

- Retail Packaging: Available in 5kg, 1kg, 500g, and smaller customized packaging, perfect for smaller-scale producers or consumer-facing businesses.

Loading Quantity in 20-ft Container:

- Palletized: 15 MT

- Non-palletized: 17 MT

Loading Quantity in 40-ft Container:

- Palletized & Non-palletized: 25 MT

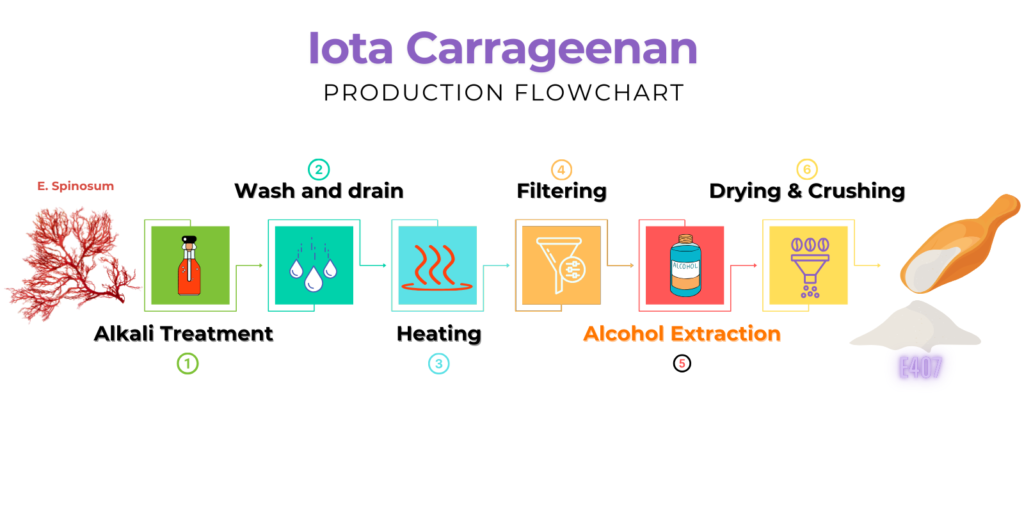

4. Manufacturing Process

Iota Carrageenan undergoes a rigorous processing procedure to ensure high purity and clarity.

The general steps include:

- Seaweed Harvesting: Sourced from the Eucheuma spinosumspecies, primarily grown in Indonesia.

- Alkali Treatment: The seaweed undergoes alkali treatment to extract the carrageenan.

- Washing & Draining: The treated seaweed is washed and drained to remove impurities.

- Heating & Filtering: The product is heated and filtered to extract the desired carrageenan.

- Alcohol Extraction: Alcohol is used to refine the carrageenan, removing unwanted fibers and increasing purity.

- Drying & Crushing: The final product is dried and crushed into a fine powder for easy use.

5. Iota Carrageenan Properties

- Solubility: Insoluble in cold water but swells upon contact. It dissolves completely in water at temperatures above 70°C, typically requiring temperatures around 80°C for full dissolution.

- Gel Formation: Iota Carrageenan forms gels in the presence of calciumsalts, providing a smooth, elastic texture at low concentrations.

- Synergistic Effects: It works synergistically with other hydrocolloids like Konjac Gum and Xanthan Gum to enhance the overall gelling and texture properties of the product.

6. Product Features

- Thickening: Enhances texture and consistency, making it ideal for a wide range of food and non-food products.

- Gelling: Forms flexible, elastic gels that are especially useful in dairy beverages and meat products.

- Water Retention: Improves moisture retention, preventing syneresis in gels and preventing dishes from becoming dry.

- Protein Stability: Helps improve the stability of proteins in products like dairy and meat.

- Improved Flavor Release: Adds elasticity in candies, improving overall sensory quality.

7. Product Applications

Iota Carrageenan is incredibly versatile, with applications across several industries due to its unique properties. It is commonly used in the following:

- Dairy Products: Helps create smooth, elastic textures in products like yogurt, cream, and dairy beverages.

- Meat Products: Prevents drying and reduces the need for added phosphates in processed meats like chicken breast and beef.

- Candy: Adds elasticity and superior flavor release to gummies, chewy candies, and marshmallows.

- Jelly and Puddings: Achieves a smooth, fresh, and elastic texture while reducing water separation.

- Pharmaceuticals and Personal Care: Iota Carrageenan is used in various applications such as capsules, emulsions, and lotions due to its gelling and stabilizing properties.

- Dietary Supplements: Provides a stable, controlled-release gel in supplements.

Recommended Dosages

- Jelly & Puddings: 0.1-0.5% – Helps to create smooth, fresh, and elastic textures while reducing syneresis, and replacing LBG.

- Candy: 0.5-1.0% – Adds elasticity and supports superior flavor release.

- Meat Products: 0.1-0.3% – Prevents drying and reduces the need for phosphate addition, ensuring a juicier product.

8. Why Choose Iota Carrageenan?

Iota Carrageenan stands out due to its superior gel formation capabilities, water retention, and versatility across various applications. It is ideal for creating smooth, elastic textures in jelly, candy, dairy products, and even meat applications. The low dosage required for gel formation in the presence of calcium ions makes it an efficient and cost-effective choice for manufacturers.

Whether you are producing high-quality dairy products, improving the texture of meat products, or making delicious candies, Iota Carrageenan is the perfect choice to enhance your product’s texture, stability, and flavor release.

Ready to enhance your products with premium Iota Carrageenan?

Contact us now for more details on our supply options and pricing.